Use of metering nozzle

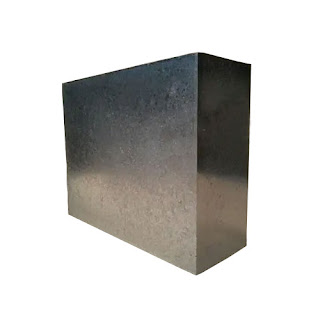

Use of metering nozzle Use of metering nozzle The metering nozzle is one of the refractory materials for billet continuous casting, and it plays the role of controlling the flow of molten steel. The molten steel flows into the mold through the metering nozzle at a constant speed and stably, which is a necessary condition to ensure the normal operation of continuous casting. As a flow control element, the tundish metering nozzle should have good anti-scour and anti-erosion capabilities. During use, the inner diameter should not expand too quickly. Once the expansion size of the metering nozzle exceeds the allowable range of the mold pulling speed, it means the sizing The nozzle has been seriously damaged and cannot be used any longer. The expansion of the metering nozzle has become a bottleneck problem in the study of improving the life of the tundish. Source: http://www.cxfirebrick.com/en/new/use-of-metering-nozzle.html Email: info@cxfirebrick.com