Application of low thermal conductivity MgO-C bricks in ladle

|

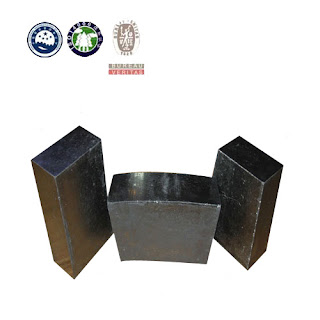

Magnesia Carbon Brick |

Measure 1: Reducing the heat transfer effect of sidewall castables (30% reduction).

This method is by reducing coarse particles in castable, increasing porosity and other measures to reduce the thermal conductivity, to suppress heat dissipation.

Measure 2: Using insulation materials in the backlayer of wall castable. This method is to use one layer insulating refractory bricks with less than 1W (m celsius) thermal conductivity between ladle steel shell and wall castable, to inhibit heat dissipationheat.

Measure 3: Reducing the heat transfer of slag line magnesia carbon brick heat transfer (30% reduction).

This method is developed in recent years, to select lower thermal conductivity of magnesite carbon bricks from the high thermal conductivity of MgO-C brick for slag line, to suppress heat dissipation.

After comparing, the results found that: only in reducing the thermal conductivity of slag line MgO-C brick , the effect of suppressing steel temperature dropping is significant, up to 2 Celsius. The durability is same or higher than ordinary ladle, less cracks, the residual condition after use is also very good.

Article source:

http://www.yilongrefractory.com/news/Application%20of%20low%20thermal%20conductivity%20MgO-C%20bricks%20in%20ladle.html

E-mail:sales8@chinaelong.com

评论

发表评论